Hydraulic Cylinder Repair in NC

When a hydraulic cylinder isn't working correctly, the entire hydraulic system suffers. If left too long, a malfunctioning cylinder could result in total system failure and lead to costly downtime. Whether your hydraulic cylinders are suffering from general wear and tear, an internal leak or some other issue, our trained technicians can help. We offer more than 25 years of experience servicing and repairing hydraulic systems and their components to keep your equipment running strong.

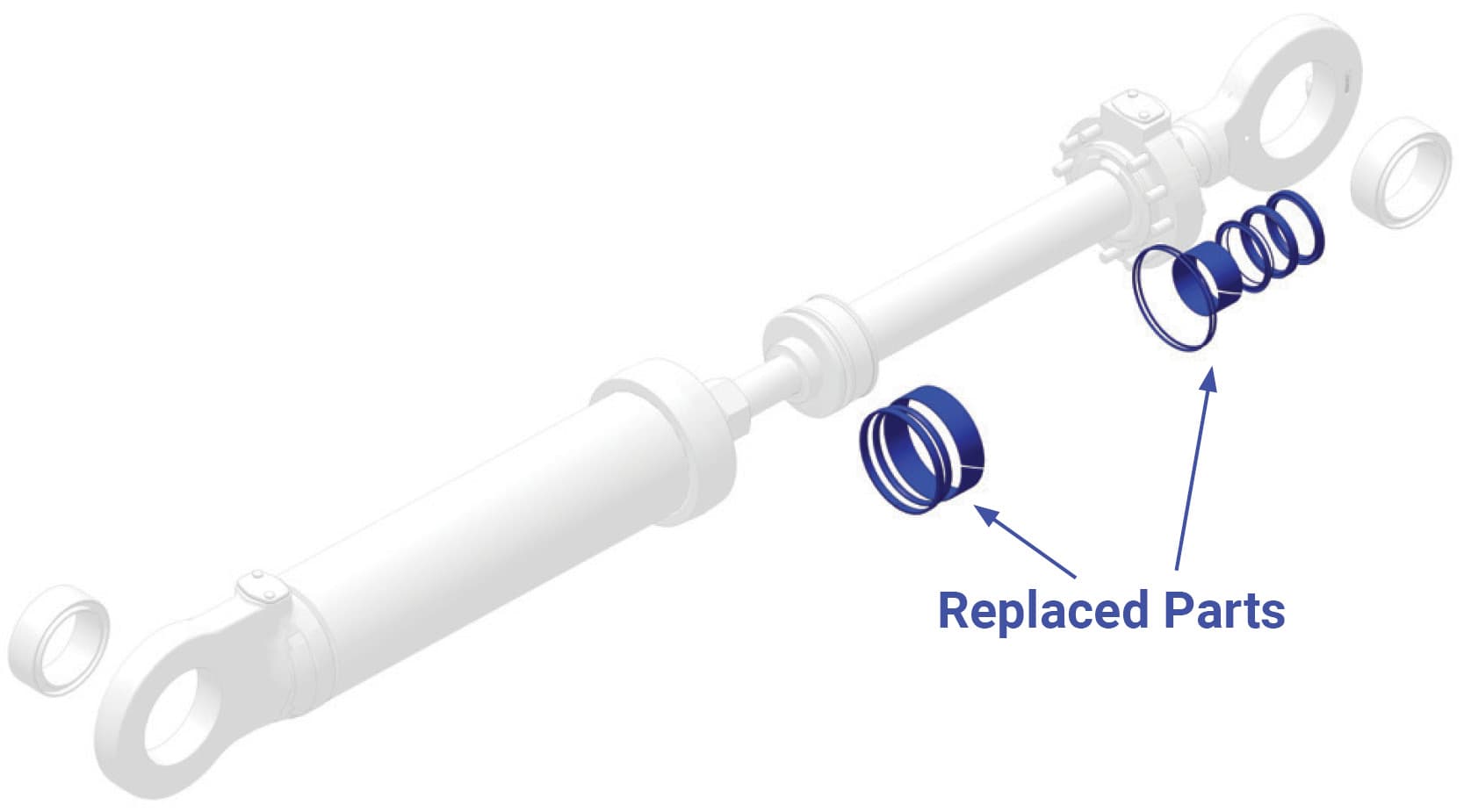

Our trained repair technicians can diagnose, repair or refurbish internal hydraulic parts, including pistons, rods, seals and more. We have experience with all brands and equipment models of hydraulic cylinders. Our repair meets and/or exceeds OEM specifications. We only use OEM replacement parts, and also offer advice on modifications to improve cylinder life and performance.

Hydraulic Cylinder Repair in Charlotte NC

Fluid contamination is one of the most common causes of hydraulic system breakdowns. Oil leaks from cylinder seals infect other parts of the cylinder, causing the system's overall integrity and performance to break down over time.

You can repair your cylinders before damage impacts your hydraulic systems with the help of the trained, highly experienced technicians in our cylinder shop. We'll quickly find a repair solution to meet your needs, whether it's a simple cleaning or reseal or a thorough repair. We offer fast, reliable hydraulic cylinder repair in North Carolina so you can move forward with the job and minimize downtime.

All incoming hydraulic cylinders are plugged and washed thoroughly before entering the shop area. They are then inspected externally and disassembled for internal inspection at one of our self-draining work areas. Each cylinder component is examined for damage and wear and the technician will prepare a quote for repair based on this assessment. Once the customer has approved the quote, the cylinder barrel will be honed and the rod will be polished to remove scratches. Then both pieces will be cleaned thoroughly before reassembly. Once the hydraulic cylinder has been reassembled, it is tested and hand-cleaned before it receives a fresh coat of paint.

Cylinder Disassembly & Repair Tooling List:

- Power team 150 ton roll bed press

- Standard 2 ½” x 6” x 10’ honing bench

- Automatic production 3” x 11 ½” x 10’ honing bench

- (5) 20’ disassembly benches

- 40’ disassembly bench

- 25,000 ft/lbs Tuxco disassembly hydraulic cylinder repair bench

- 60,000 ft/lbs Tuxco disassembly bench

Contact Hydraulics Express Today for More Information

Call us at (800) 278-9078 or reach out online to learn more about our cylinder repair services.

Contact

Company

PARTS

Services

Stay in Touch

Hydraulics Express is proud to be a part of the Weisiger Group.

A TRUSTED PARTNER IN YOUR SUCCESS.

Copyright © 2025

All Rights Reserved.

Cookie Policy | Privacy | Legal Notice | Labor Policy | Sitemap